Sanding line 4 side straight / curved parts+84 28 73036536Free ordering and advice

product detail

Salient features:

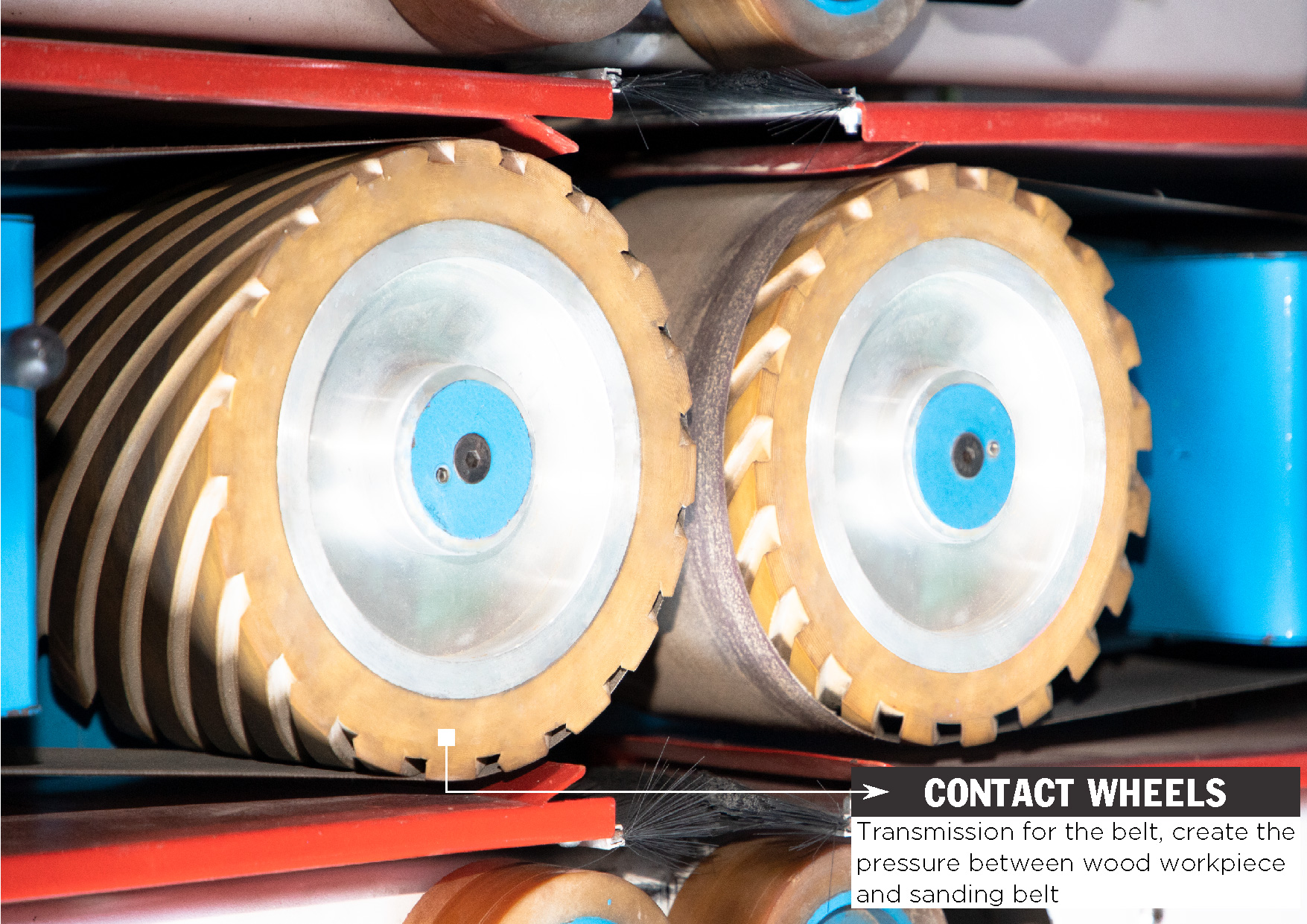

- Strong power, using rubber shaft and brush shaft with large diameter

- Sanding 4 sides of the product

- Various scrubs with curved wood profiles

- High finish, flat wood surface, glossy, clean wood hair

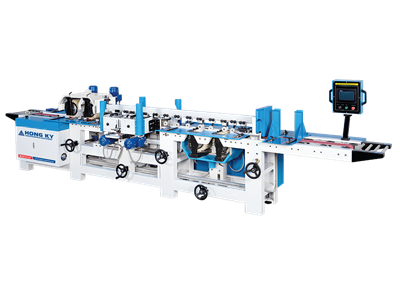

The line includes 5 machines:

(1) Upper and lower edge band sander

(2) Side Band Sander

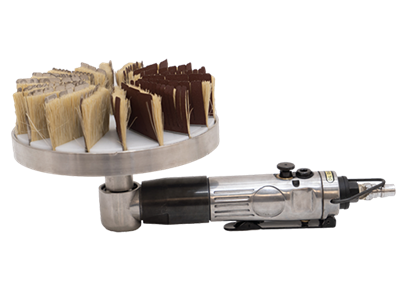

(3) Top and bottom disc brush sander machine

(4) Side brush sander

(5) Upper and lower edge brush sander

Application: Wide range of sanding for curved wood parts, length 350mm or more. Scrub before paint and rub off primer.

The CES line closely and flexibly combines a smoothing tape and a sanding brush, resulting in high quality finished wood products, with a smooth, even surface.

The product has the following outstanding advantages:

1. High working productivity

When using the CES line, the wood goes through 5 sanding machines in turn and is finished with 4 wood surfaces.

At the same time, all machines are capable of flexibly adjusting, users can control work productivity at a high level.

2. Tightly combine abrasive belt, abrasive disc and brush shaft

With the oscillation of the abrasive belt, which rotates continuously, direct contact with the wood edge helps the wood workpiece to become flat, removing the original ripple marks.

After being smoothed, the edges are immediately reduced to a sharp, shiny finish thanks to a combination of disc sanding units located above and below the workpiece path.

Finally, 2 sanders on the bottom and 2 edges, strong power will completely remove wood hair, smooth and glossy surface. All parts combine closely and flexibly to complete the wood billet, providing both high capacity and maximum quality response.

3. Easy to use, save labor

The product is intelligently designed with a rubber roller that holds the wood billet head in place, helping the wood workpiece even in curved contours, but the abrasive tapes or brush shafts are always rubbed with high efficiency.

In addition, the replacement of abrasives with the machines in the line is also extremely simple, easy to assemble and use.

Hong Ky commits to always accompany the customer during the installation and operation of the machine. Besides, we also always bring the most effective sanding solutions for each wood material.

PRODUCT PARAMETER:

| Specification | Value |

| Operating voltage | 3 phase – 380V ± 5% / 50Hz |

| Working width | 20 – 100 mm |

| Minimum working length | 350 mm |

| Working height | 20 – 100 mm |

| Curvature part wood – radius | ≥1000 mm |

| Rolling speed | 2 – 15 m/min |

| Conveyor speed | 2 – 15 m/min |

| Length of conveyor | 2 x 0.5 m, 4 x 1.0 m |

| Working height of conveyor | 850 – 900 mm |

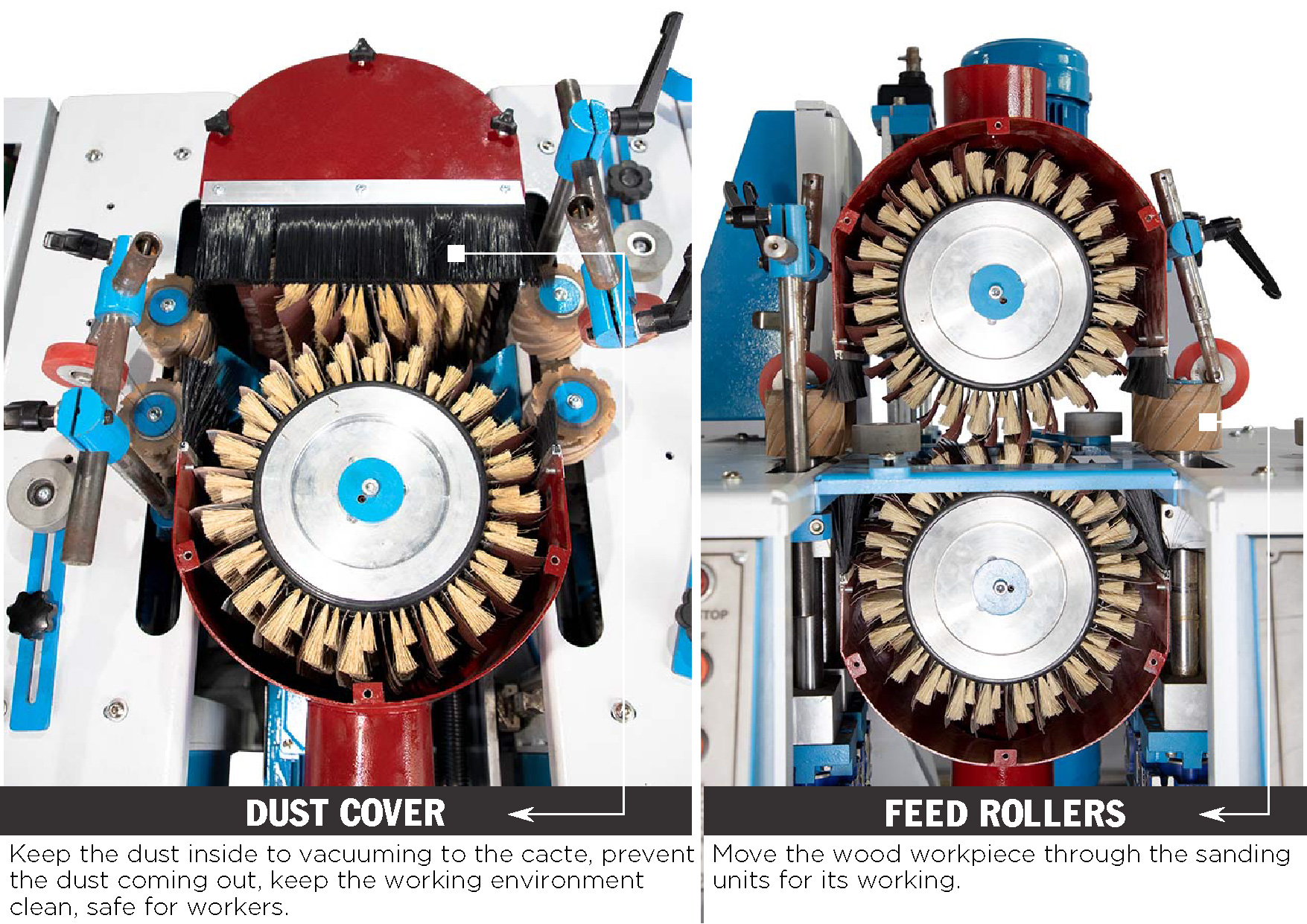

| Dust extraction hood | 10 x Ø100 mm |

| Air speed | 30 m/s |

| Air volume / Dust extraction | 7400 m³/h |

| Size of line (LxWxH) | 9000 x 1620 x 1800 mm |

| Line net weight | 2350 kg |

| Total power | 13.4 kW |

Video:

product relative

Address: Hamlet 4, Huu Thanh Ward, Duc Hoa district, Long An province

Trading places: 38 Tay Lan,7 Quarter, Binh Tri Dong A Ward, Binh Tan District, HCM city

© 1986 - 2020 Hong Ky Corporation

Business license No. 0302268557 by Department of Planning and Investment of Ho Chi Minh City.